Challenges Facing the 623-483-04 Screws Industry

Exploring the 623-483-04 Screws Industry

While screws may not be synonymous with rapid technological advancements, the 623-483-04 screws industry is a dynamic niche that serves critical functions in fields ranging from aerospace to consumer electronics. Despite their essential role in ensuring the integrity of complex systems, several challenges continue to hold this sector back. In this article, we’ll delve into these hurdles, providing insights into what limits growth and exploring opportunities for innovation.

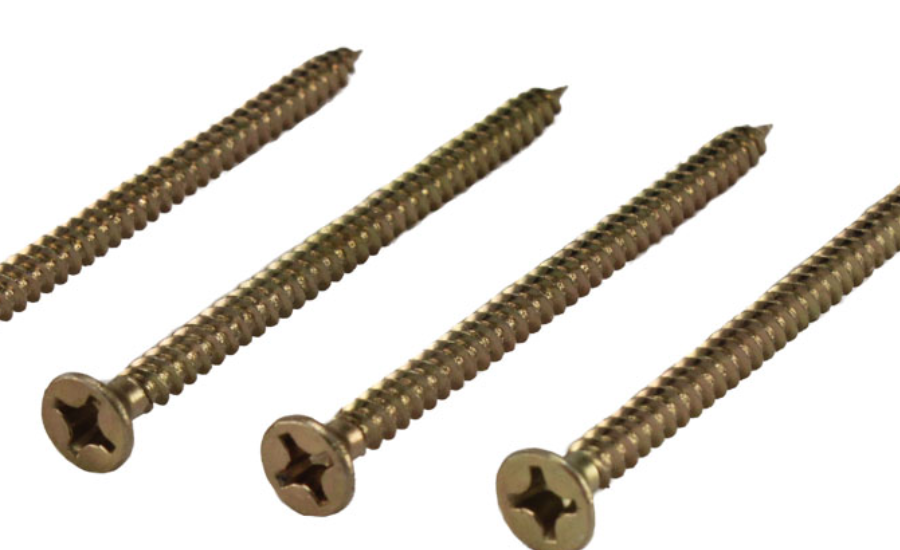

A Closer Look at 623-483-04 Screws

What Are 623-483-04 Screws?

The 623-483-04 screws are highly specialized fasteners designed to perform in extreme, high-stress environments. Known for their remarkable durability, precision engineering, and ability to withstand demanding conditions, they are commonly utilized in industries like aerospace, automotive, and heavy machinery, where reliability is non-negotiable.

Why Are They Critical?

The importance of 623-483-04 screws lies in their ability to maintain the structural integrity of critical systems. For example, in aerospace applications, even a minor defect in a single screw can result in catastrophic consequences. Their performance directly affects the safety and efficiency of entire operations, making their reliability a top priority.

Key Applications

The versatility of 623-483-04 screws spans multiple industries, from securing aircraft components to fastening parts in automotive systems. These screws are also found in industrial machinery, medical devices, and some consumer electronics, reflecting their adaptability across a wide range of applications. Their unmatched reliability ensures they remain indispensable in these sectors.

The Supply Chain Bottleneck in the 623-483-04 Screws Industry

Raw Material Shortages

One of the most pressing challenges for manufacturers of 623-483-04 screws is the scarcity of high-quality raw materials. These metals, essential for producing durable screws, are not always easily accessible. The result? Delayed production schedules and higher costs, which impact the entire supply chain.

Manufacturing Delays

Even with sufficient raw materials, the process of manufacturing these screws is slow and labor-intensive. Precision is key—every screw must meet exacting standards. Any deviation can result in a product that fails to meet safety requirements, leading to additional delays as faulty products must be discarded or reworked.

Transportation Disruptions

Transporting these screws from the factory to the customer presents another set of challenges. Global transportation disruptions, whether due to geopolitical tensions, natural disasters, or logistical constraints, can severely delay shipments. These challenges only add to the complexity of ensuring a smooth supply chain.

Quality Control Challenges for 623-483-04 Screws

Strict Testing Standards

Given the high-stakes applications of 623-483-04 screws, rigorous testing protocols are essential. However, these stringent quality checks require significant time and financial investment. Testing every batch of screws to meet these standards adds to both the cost of production and the time it takes to bring products to market.

Inconsistent Global Standards

The standards that define a “high-quality” screw can vary greatly between industries and countries. This lack of consistency can create confusion for international manufacturers and suppliers, making it difficult to meet diverse regulatory requirements and ensure uniform quality across global markets.

Consequences of Defective Products

Defective screws can have devastating consequences, particularly in industries like aerospace, where a single faulty fastener can endanger lives. Therefore, ensuring consistent quality isn’t just a matter of compliance—it’s critical for the safety of entire systems.

Technological Barriers in the Industry

Outdated Production Techniques

Many manufacturers in the 623-483-04 screw industry still rely on older, inefficient production methods. While some companies have adopted more advanced techniques like CNC (computer numerical control) machining, others lag behind, resulting in lower efficiency and product quality.

Innovation Lag

Innovation in this field has been slow, mainly due to the substantial costs associated with research and development. Companies hesitant to invest in cutting-edge technologies risk falling behind, reducing competitiveness and stalling industry growth.

Limited Automation

Automation could drastically improve the efficiency and quality of screw production, but its implementation is costly. Many smaller manufacturers are reluctant to invest in automated systems due to the initial expense, limiting their ability to scale production and meet growing demand.

Economic Pressures Affecting the Market

High Production Costs

The specialized nature of 623-483-04 screws, along with the use of high-quality materials and precision engineering, makes them expensive to produce. These high production costs often translate to higher prices for customers, which can stifle market expansion.

Market Instability

Economic fluctuations—such as volatile raw material prices, changes in labor costs, or currency fluctuations—can make it difficult for manufacturers to maintain profitability. These uncertainties add another layer of complexity to an already competitive market.

Intense Competition

The market for 623-483-04 screws is highly competitive, with numerous players vying for dominance. This competition can lead to price wars that squeeze profit margins, leaving little room for companies to invest in future innovations or improvements.

Navigating Regulatory Obstacles

Strict Industry Regulations

In industries like aerospace and healthcare, the regulatory standards for 623-483-04 screws are stringent. While these regulations ensure safety, they also present barriers to entry for new manufacturers. The cost and complexity of meeting these standards can deter potential competitors from entering the market.

Cost of Compliance

Complying with industry regulations is expensive. From obtaining certifications to maintaining ongoing quality assurance, the costs associated with compliance can be prohibitive, especially for smaller companies.

Global Regulatory Challenges

For businesses looking to expand internationally, navigating the complex web of regulations in different countries can be daunting. Each nation has its own standards for product quality, creating challenges for companies trying to achieve compliance across multiple regions.

Addressing Environmental Concerns in the Industry

Sustainability Challenges

The production process for 623-483-04 screws can have significant environmental impacts, from the extraction of raw materials to manufacturing and transportation. Reducing this footprint is an increasing concern, but finding sustainable solutions remains a challenge.

Waste Disposal Issues

Proper waste management, including the disposal or recycling of defective screws, is often overlooked. Inefficient practices can not only harm the environment but also result in regulatory penalties, further complicating an already complex industry landscape.

Shift Toward Green Technologies

Although there is growing interest in adopting eco-friendly manufacturing methods, the transition has been slow. The cost of investing in sustainable technologies is high, and the long-term benefits may not always be immediately visible, making it difficult for companies to justify the expense.

Addressing the Skilled Labor Shortage

Need for Specialized Skills

The production of 623-483-04 screws requires a skilled workforce with specialized knowledge. However, a shortage of such expertise is hindering production, leading to delays and quality concerns across the industry.

Training Investments

Training employees to meet the rigorous standards required in this field is both time-consuming and costly. Companies must continually invest in employee development to ensure their workforce is equipped with the latest techniques and knowledge.

Innovation at Risk

The labor shortage isn’t just affecting production; it’s also stifling innovation. Without skilled professionals to experiment with new materials and techniques, the industry risks stagnation, limiting future growth and advancements.

The Crucial Role of Research and Development

Driving Innovation

Research and development (R&D) are essential for the evolution of the 623-483-04 screw industry. R&D efforts can result in the discovery of new materials, improved production techniques, and overall better product quality.

Securing R&D Funding

However, securing funding for R&D initiatives, especially for smaller companies, is often challenging. While government grants and subsidies can help, they are not always accessible, leaving many businesses without the necessary resources to innovate.

Collaborative Innovation

Collaborative efforts between industry leaders, academic institutions, and government bodies can foster innovation. Joint research projects allow companies to pool resources and knowledge, leading to industry-wide advancements that benefit all stakeholders.

Boosting Market Awareness

Educating the Consumer

Many consumers and end-users may not fully understand the importance of using high-quality 623-483-04 screws. Raising awareness about the benefits of these screws can help drive demand and justify their higher price points.

Effective Marketing Strategies

Strong branding and marketing can differentiate companies in a crowded marketplace. Highlighting the unique qualities and benefits of their screws can attract more customers and foster brand loyalty.

Digital Marketing Opportunities

Leveraging digital platforms offers manufacturers the opportunity to reach a broader audience. By utilizing websites, social media, and online marketplaces, companies can showcase their products and educate potential buyers on the advantages of choosing high-quality screws.

Future Trends and Opportunities for 623-483-04 Screws

The Emergence of Advanced Materials

Research into stronger, lighter, and more durable materials is set to transform the 623-483-04 screws industry. Advanced alloys and composites could significantly improve the performance and lifespan of screws, opening new doors for innovation.

Automation and Artificial Intelligence

Automation and artificial intelligence (AI) are poised to revolutionize the production process for screws. AI can optimize manufacturing workflows, while predictive analytics can help anticipate maintenance needs, minimizing downtime and enhancing efficiency.

Global Market Expansion

As emerging markets continue to grow, opportunities for global expansion abound. Companies that can successfully navigate the complex regulatory environments of these regions and establish a presence stand to benefit from significant growth potential.

Summary

The 623-483-04 screws industry, which caters to high-stress applications like aerospace, automotive, and industrial machinery, faces significant challenges despite the critical role these screws play in ensuring structural integrity and safety. Key hurdles include raw material shortages, manufacturing delays, quality control issues, and high production costs. Additionally, the industry contends with outdated production techniques, limited automation, and inconsistent global standards, which create obstacles for manufacturers. Environmental concerns, such as waste disposal and sustainability, along with skilled labor shortages, further exacerbate these challenges. However, opportunities for innovation through research and development (R&D), advanced materials, and automation remain crucial for the industry’s growth. Increasing market awareness through digital marketing and expanding into global markets also presents potential for future expansion.

FAQs

1. What are 623-483-04 screws?

623-483-04 screws are highly specialized fasteners engineered to withstand extreme conditions, making them essential in industries such as aerospace, automotive, and heavy machinery.

2. Why are 623-483-04 screws important?

These screws maintain the structural integrity of complex systems. In critical industries like aerospace, even a small defect can lead to catastrophic failures, making their reliability paramount.

3. What are the main challenges facing the 623-483-04 screws industry?

Challenges include raw material shortages, manufacturing delays, transportation disruptions, strict quality control standards, and high production costs. The industry also faces outdated production methods, limited automation, and regulatory hurdles.

4. How does the industry address environmental concerns?

Environmental concerns include sustainability challenges in raw material extraction, waste disposal, and the slow adoption of eco-friendly technologies. Although some companies are beginning to adopt green technologies, progress has been slow due to the high costs involved.

5. How does the skilled labor shortage affect the industry?

The shortage of skilled labor hinders production, leading to delays and quality issues. Additionally, a lack of expertise stifles innovation, which could limit future advancements in screw manufacturing.

6. What role does research and development play in the industry’s future?

R&D is crucial for driving innovation, discovering new materials, and improving production techniques. However, securing funding for R&D, especially for smaller companies, remains a challenge. Collaborative efforts between industry, academia, and government can foster significant advancements.

7. How can companies in the 623-483-04 screws industry differentiate themselves?

By investing in digital marketing strategies, raising consumer awareness about the benefits of high-quality screws, and adopting advanced technologies, companies can distinguish themselves in a competitive marketplace.

8. What future trends are expected in the 623-483-04 screws industry?

Emerging trends include the use of advanced materials to improve screw performance, automation and AI integration for production optimization, and expansion into global markets as demand grows in emerging regions.

Stay engaged for the latest news and alerts! Washington Breeze